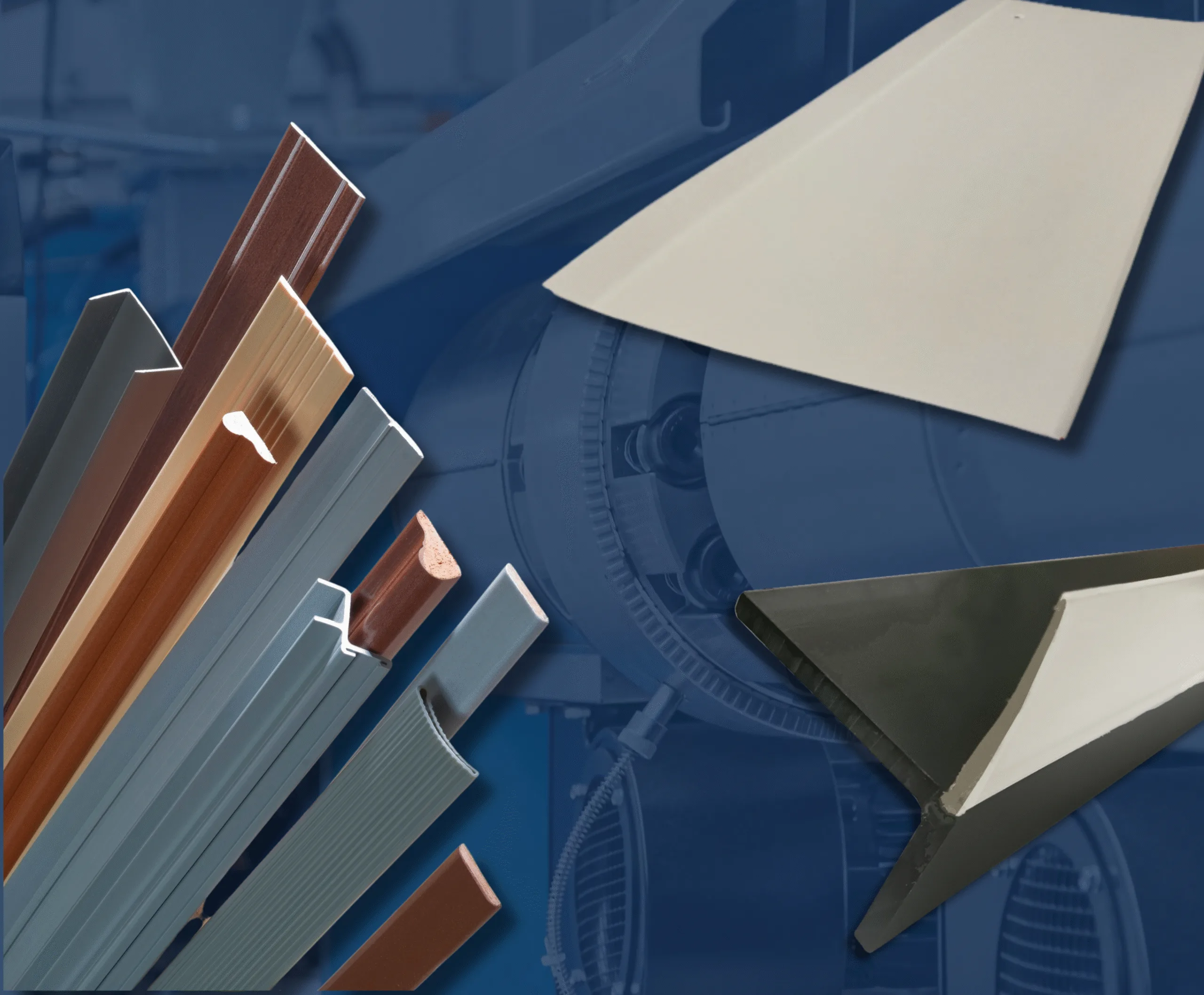

Profile Extrusion

Profile Extrusion is a specialized plastic manufacturing process that produces continuous shapes with consistent cross-sections, such as window frames, tubing, and seals. This method involves feeding thermoplastic materials into an extruder, where they are melted and forced through a custom-designed die to form the desired profile. The extruded shape is then cooled and solidified, ensuring dimensional accuracy and structural integrity. Profile extrusion is versatile, accommodating both solid and hollow forms, and is widely used across industries like construction, automotive, and medical due to its efficiency and ability to produce complex, customized designs.

Complete service for the development and production of plastic profile extrusions.

Our Comprehensive Services Encompass

- Concept

- Design

- Tool Fabrication

- Production

Services

- One-Stop Services

- Customise Services

- Material Selection and Specification

- Colour Matching

- Tools Fabrication

- Product Design

Production Facilities

- Profile Extrusion Capacity: 2 to 200kg/h

- On Line Secondary Operation

Our Product Range Includes

- Simple Open Profile

- Complex Multi-Chamber Closed Profile

- Co-Extrusion of Two Different Materials

Materials

- Flexible and Rigid P.V.C.

- High Impact P.V.C.

- Rigid Foam P.V.C.

- Non-Migration, Oil Resistant and Heat Resistant P.V.C.

- Thermoplastic Elastomer (T.P.E.)

- Thermoplastic Alloys

- Polyurethane (PU)

- Thermoplastic Polyurethane (T.P.U.)

- ABS and etc.

Structural Wood is a synthetic wood. It is formed by foamed synthetic polymer and exudes a brisk wood tincture / texture.

The advantages are:

- Concept

- Design

- Tool Fabrication

- Production

On top of its other benefits, Structural Wood is easy to work with (like real wood) and can be bent when hot to save time. You also don’t need to polish or paint it.

You can find Structural Wood used a lot to make furniture, decorate inside buildings, and in construction.

Structural Wood is an environmentally friendly product that is durable and recyclable.